Electric generators are a crucial part of many industries and households, providing power during emergencies or when a regular power source is not available. Why Electric Generators Need Proper Fuel Filters. However, these generators can become unreliable or even dangerous if they are not properly maintained. Fuel filters are a vital component of electric generators, ensuring that the engine receives clean fuel free from contaminants that can cause damage. Without proper fuel filters, electric generators can quickly malfunction, leading to costly repairs or replacements.

Therefore, it is essential to understand the importance of proper fuel filters for electric generators. In this article, we will explore the different types of fuel filters available, how to choose the right one, and how to maintain and replace them. We will also discuss the cost of neglecting fuel filters and the different types of fuel contaminants that can affect electric generators.

By the end of this article, you will have a better understanding of why fuel filters are critical for electric generators and how to ensure that your generator is working efficiently and safely.

Understanding Electric Generators

Electric generators are essential devices that convert mechanical energy into electrical energy, making them a vital component of various industries and settings. They come in different sizes and are used in many applications, from powering small homes during blackouts to supplying electricity to entire cities.

In residential settings, portable generators are often used for camping or as a backup power source during emergencies. In commercial and industrial settings, electric generators are used for various purposes, including construction sites, hospitals, data centers, and manufacturing plants.

Standby generators are commonly used in residential and commercial settings to provide backup power during power outages. These generators are designed to automatically turn on when the main power source fails, ensuring that critical systems remain operational.

Towable generators are commonly used in construction sites, remote locations, and events. These generators are mounted on trailers and can be transported to different locations, providing power where it is needed most.

Overall, electric generators play a crucial role in many industries and settings, providing reliable and efficient power when and where it is needed most.

What Are Fuel Filters?

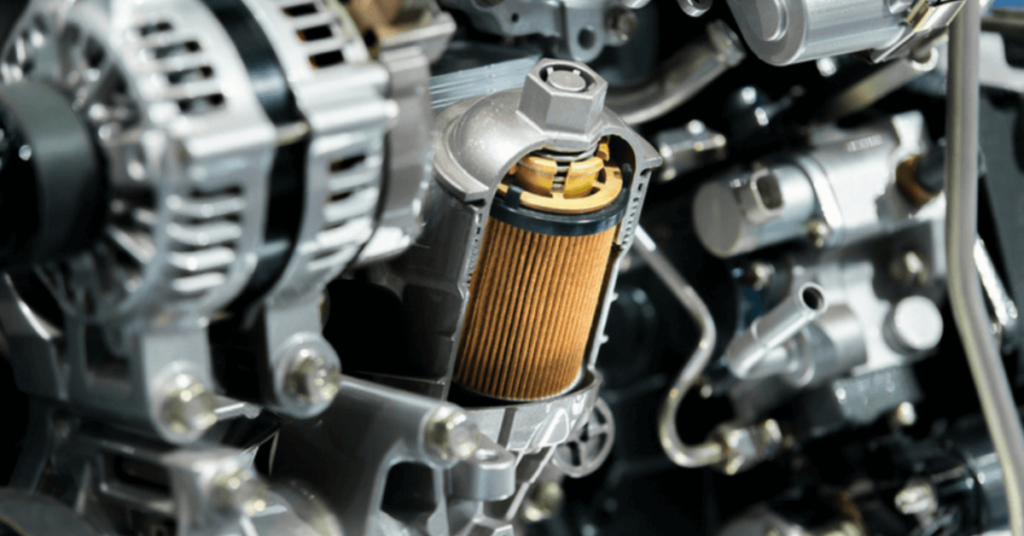

Fuel filters play a crucial role in ensuring the smooth operation of combustion engines, including electric generators. These filters are designed to remove impurities from the fuel, such as dust, rust, and water, that can cause damage to the engine. When fuel is delivered to the engine, it passes through the fuel filter first, allowing the filter to trap any contaminants before they reach the engine. By keeping the fuel clean, the fuel filter helps to extend the life of the engine and reduce the risk of expensive repairs or replacement.

There are two main types of fuel filters used in electric generators: inline filters and spin-on filters. Inline filters are placed in the fuel line, between the fuel tank and the engine, and require a separate mounting bracket to hold them in place. Spin-on filters, on the other hand, are screwed directly onto the fuel pump or fuel tank, making them easier to install and replace. Both types of filters work effectively in trapping impurities and ensuring clean fuel is delivered to the engine. The choice between the two will depend on the make and model of the generator and the manufacturer’s recommendations.

Importance of Proper Fuel Filters for Electric Generators

Electric generators require proper fuel filters to function efficiently and safely. A fuel filter plays a crucial role in ensuring that the fuel that reaches the engine is free from contaminants that could cause damage or malfunction. Contaminants such as dust, dirt, and water can easily enter the fuel tank and eventually reach the engine, leading to a reduction in performance, stalling, or complete engine failure.

A clogged fuel filter can also cause the engine to work harder, resulting in reduced fuel efficiency and increased wear and tear on the engine. This can lead to costly repairs or even engine replacement. In addition to preventing damage to the engine, fuel filters also help to extend the engine’s life by ensuring that it operates under optimal conditions, reducing the risk of expensive repairs or replacement. Proper fuel filtration is, therefore, crucial for the efficient and safe operation of electric generators.

Types of Fuel Contaminants

Fuel contaminants are any particles or impurities that can be found in fuel. They can include dust, dirt, rust, and water. Diesel fuel is particularly prone to contamination, as it is often stored for long periods, leading to the growth of bacteria and fungi that can damage the engine.

Choosing The Right Fuel Filter For Your Electric Generator

When choosing the right fuel filter for your electric generator, it is crucial to consider several factors. One of the primary factors is the type of generator you have. Different types of generators require different types of filters. For example, portable generators may require a different type of filter than a standby generator.

The fuel source is also an essential consideration when selecting the appropriate filter. Different fuel types, such as gasoline, diesel, or propane, require different types of filters. Gasoline generators typically use paper filters, while diesel generators often use water separator filters or a combination of both paper and mesh filters.

Another factor to consider is the expected use of the generator. If the generator is used in a dusty or dirty environment, a filter with a higher filtration capacity, such as a mesh filter, may be required to prevent contamination from damaging the engine.

Ultimately, selecting the right fuel filter for your electric generator will depend on the specific requirements of your generator and its operating environment. It is always recommended to consult with the manufacturer’s guidelines or a qualified technician to ensure that you choose the appropriate filter for your generator.

Maintaining Your Electric Generator’s Fuel Filter

Proper maintenance of your electric generator’s fuel filter is crucial to ensure that it performs efficiently and has a long lifespan. To maintain your fuel filter, it should be checked regularly for signs of damage, wear, or clogging. If you notice any of these signs, you should clean or replace the fuel filter according to the manufacturer’s guidelines.

It is also essential to ensure that the fuel source is clean and free from contamination. Before adding fuel to your generator, it is advisable to inspect it for any impurities or debris. Using contaminated fuel can cause your fuel filter to become clogged and reduce the efficiency of your generator. Additionally, it can cause damage to the engine, leading to costly repairs or replacement.

To ensure the longevity and efficient operation of your fuel filter, you should follow the manufacturer’s recommended maintenance schedule. This may include regular cleaning or replacement of the filter, depending on the frequency of use and the quality of fuel used.

Regular maintenance of your fuel filter can help to avoid costly repairs and ensure that your electric generator runs efficiently and reliably. Therefore, it is crucial to make fuel filter maintenance a regular part of your generator’s maintenance routine.

Signs Yhat Your Electric Generator’s Fuel Filter Needs To Be Replaced

If you notice any of the signs mentioned above, it is crucial to take immediate action and replace the fuel filter as soon as possible. Ignoring these signs can lead to more severe problems, such as engine damage, which can be expensive to repair. Other signs that your fuel filter needs to be replaced include a visible buildup of debris or discoloration of the fuel, unusual engine noises or vibrations, and a strong fuel odor.

If you are experiencing any of these symptoms, it is recommended that you stop using the generator immediately and have it inspected by a professional technician. They will be able to diagnose the problem and determine whether the fuel filter needs to be replaced or if there is a more significant issue with the engine.

Regular maintenance and replacement of your electric generator’s fuel filter can help to prevent these issues from occurring and ensure that your generator runs smoothly and efficiently for years to come.

How To Replace Your Electric Generator, Fuel Filter

Replacing your electric generator’s fuel filter is a simple process that can be done with a few basic tools. The first step is to locate the filter, which is typically located near the fuel pump or tank. The old filter can then be removed by unscrewing it or cutting it off using pliers. The new filter can then be installed, making sure to follow the manufacturer’s instructions for proper installation. Once the new filter is in place, it is important to check for leaks and to start the generator to ensure that it is functioning correctly.

The Cost Of Neglecting Your Electric Generator’s Fuel Filter

Neglecting your electric generator’s fuel filter can have several costly consequences. Firstly, it can cause the generator to malfunction or fail, resulting in expensive repairs or replacements. A clogged or damaged fuel filter can allow impurities to enter the engine, leading to damage to the fuel injectors, carburetors, or other critical engine components. These repairs can be expensive and time-consuming, causing interruptions to your operations and significant financial costs.

Secondly, a neglected fuel filter can reduce the efficiency of the generator, leading to increased fuel consumption and higher operating costs. Dirty or clogged fuel filters can cause the generator to work harder than necessary, consuming more fuel and reducing the generator’s overall performance. Over time, this can add up to significant increases in operating costs, reducing the profitability of your operations.

Finally, a malfunctioning generator can also pose a safety risk, especially in situations where backup power is critical, such as hospitals or data centers. A generator that fails to start or that runs poorly can cause fires or explosions, endangering the safety of your staff and customers.

To avoid these costly consequences, it is essential to perform regular maintenance on your electric generator’s fuel filter, including cleaning or replacement as needed. Regular maintenance can help to ensure that your generator runs smoothly and reliably, providing you with the power you need when you need it most.

How To Extend The Life Of Your Electric Generator’s Fuel Filter

To ensure that your electric generator’s fuel filter lasts as long as possible, there are several best practices you can follow. Firstly, it is crucial to ensure that the fuel source is clean and free from contamination. This means storing the fuel in a clean and dry place and using fuel additives to prevent the growth of bacteria and fungi.

Secondly, regular maintenance is essential to keep the fuel filter working efficiently. This includes cleaning or replacing the filter as needed, according to the manufacturer’s guidelines. It is also important to check the filter regularly for signs of wear, damage, or clogging.

Finally, choosing a high-quality fuel filter with excellent filtration efficiency can help to extend the life of the filter and the generator. High-quality filters can remove more contaminants from the fuel, reducing the risk of engine damage and malfunction. When choosing a fuel filter, it is essential to consider the type and quality of the filter, as well as the specific needs of your generator.

By following these best practices, you can ensure that your electric generator’s fuel filter lasts as long as possible, keeping your generator running smoothly and reliably for years to come.

FAQs

What is the lifespan of fuel filters in electric generators?

The lifespan of fuel filters can vary depending on several factors, including the type of filter, the quality of fuel, and the frequency of use. Generally, fuel filters should be replaced every 100 to 300 hours of use, or at least once a year.

How often should fuel filters be replaced in electric generators?

Fuel filters should be checked regularly for signs of damage, wear, or clogging. They should be cleaned or replaced as needed, according to the manufacturer’s guidelines. Generally, fuel filters should be replaced every 100 to 300 hours of use or at least once a year.

Can you clean a fuel filter instead of replacing it?

In some cases, it may be possible to clean a fuel filter instead of replacing it. However, it is essential to follow the manufacturer’s guidelines and to ensure that the filter is thoroughly cleaned and free from debris before reinstallation.

Do all electric generators have fuel filters?

Most electric generators have fuel filters, as they are essential for the efficient and safe operation of the engine. However, the type and quality of the filter can vary depending on the generator’s make and model.

What are the common types of fuel filters used in electric generators?

The most common types of fuel filters used in electric generators include paper filters, mesh filters, and water separator filters.

Conclusion

In conclusion, proper fuel filters are crucial for ensuring the efficient and safe operation of electric generators. Neglecting to install and maintain the correct fuel filter can lead to fuel contamination, engine failure, and costly repairs or replacements. Choosing the right filter for your specific generator model, fuel source, and expected usage, and keeping up with regular maintenance and replacement schedules is necessary to ensure that the filter is operating at peak efficiency.

By following these best practices, you can extend the lifespan of your generator, improve fuel efficiency, and prevent unexpected downtime, all while ensuring that your generator runs smoothly and reliably for years to come.